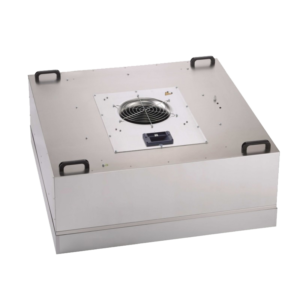

1 Filtration

For ISO 14644 compliant environments, H14 HEPA filtration is required. This can be delivered via terminal filters connected to air handling units (AHUs) via ductwork or as individual Fan Filter Unit (FFU) modules directly ducted or drawing supply air from a shared plenum.

HEPA filtration can also be placed on the exhaust via plenum boxes or specialist safe change units to facilitate containment or eliminate cross contamination.

Download Data Sheet

GT Flow Max is a new generation energy-saving Fan Filter Unit with superior performance and reduced power consumption by more than 50% – featuring Roomside Filter Change as standard and a gel seal.

GT Flow Pro is a robust, reliable Fan Filter Unit (FFU) with an efficient AC motor and H14 HEPA filters, which helps to deliver on low energy consumption. This FFU implements a gel seal.

GT Flow Plus is Guardtech’s mid-level Fan Filter Unit (FFU) – featuring an efficient AC motor which helps to deliver on low energy consumption, this FFU implements a gasket seal.

GT Flow Lite is Guardtech’s entry-level fan filter unit – it’s the perfect solution for creating cleanrooms with vertical laminar flow. These are typically installed in false ceilings with proper aluminium profiles.

This product range does not currently include a Fire Rated solution. Please consult a Guardtech rep for more information on your fire safety options.

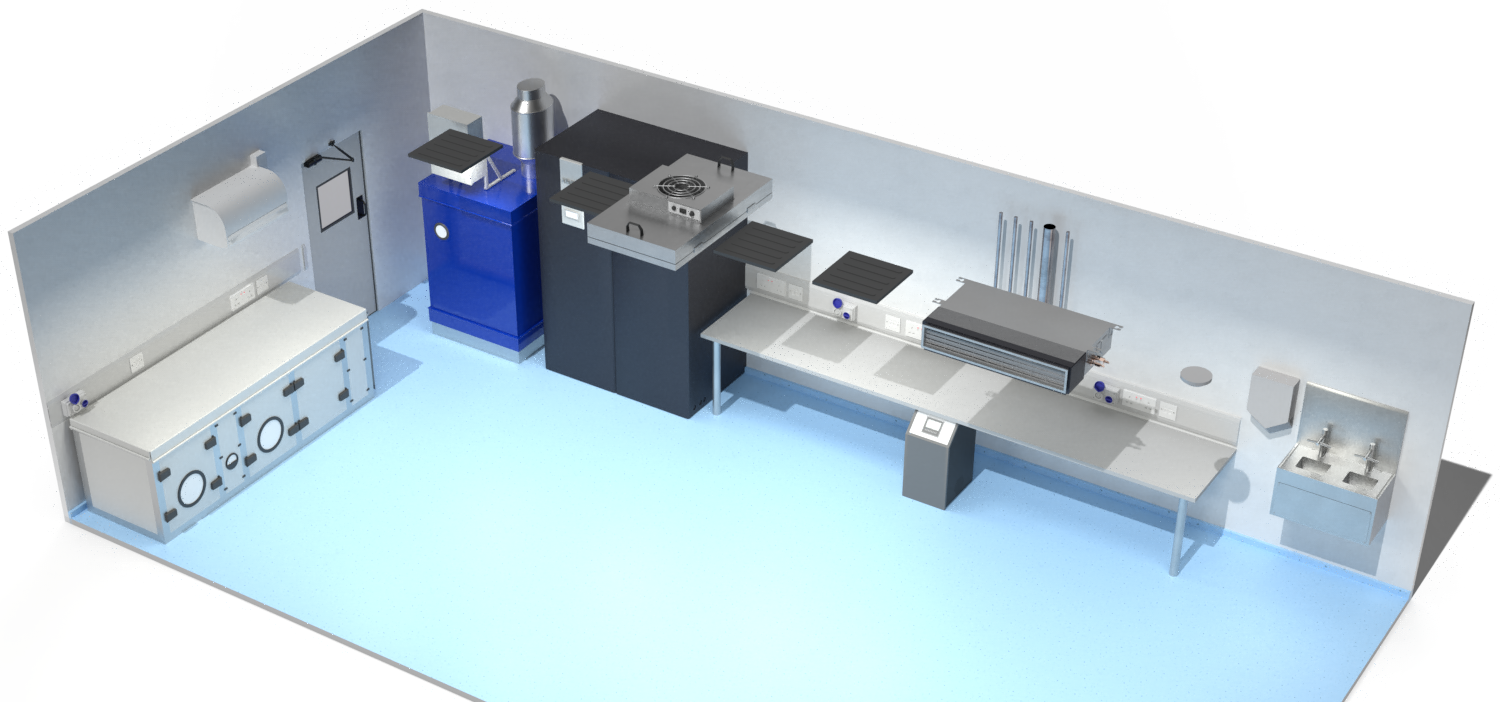

2 HVAC

Air treatment and air movement are fundamental principles that must be considered in every cleanroom design. Filtration naturally plays an essential part in achieving classification, however, the methodology of moving air through that media must also be considered.

Added to air movement are the principles of air treatment or conditioning, this may include heating, cooling, humidification and dehumidification. The parameters to which these must be controlled and the accepted tolerances balanced against the constraints of the budget will be the guiding influence behind the decision-making process.

Guardtech Cleanrooms have all your HVAC bases covered, from bespoke air handling units (AHUs) to upflow units, fan coil units to wall-mounted cassettes. Whatever the needs of your application, we have the HVAC solution.

Download Data Sheet

Guardtech’s elite-level air conditioning solution – these high-performance Air Handling Units (AHUs) provide optimum temperature and humidity conditions for a diverse range of applications.

Guardtech’s upper mid-level air conditioning solution – a high-specification upflow unit that offers precision temperature and humidity control to ensure optimum conditions in your cleanroom.

Guardtech’s lower mid-level air conditioning solution – a ducted system that uses a powerful fan coil unit to deliver the ideal temperature and humidity conditions for your cleanroom.

Guardtech’s entry-level air conditioning solution – a wall-mounted cassette (for CNC/laboratories) which can be placed in the CleanCube plenum for cleanrooms.

This product range does not currently include a GT Fire solution. Please contact the team to discuss your options.

3 PROCESSED GAS DISTRIBUTION

Highly filtered compressed air can be provided with compressors, filtration, transair pipework and a range of fittings for process requirements.

In addition, a vast range of gasses, either from cylinder or generator, can be integrated into the facility design with appropriate pipework, valves and manual or digital control systems with appropriate alarms where required.

4 Extraction

Fumes such as solvents and acids, particulate – such as powders and fibres – and heat can all be directly extracted at source from the controlled environment.

Extraction ductwork material is selected based on the characteristics of the by-product extracted, powered through fans and exhausted at a high level, in some cases via filtration media such as HEPA, ULPA or carbon. Alternatively, extract can be filtered via scrubbers and returned to the supply air stream.

5 Purified Water

For volume manufacturing of Pharmaceuticals and Semiconductor products, purified water is often required. We can install a variety of systems for process integration, including all plant, distribution systems, pipework and fixtures and fittings.

Ranging from low grade DI water systems with localised distribution all the way through to US Pharmacopoeia compliant closed loop 316L stainless steel FWI systems.

6 Vacuum

House vacuum for cleaning activities can be provided via a centralised vacuum system.

This enables a number of rooms to have a wall-mounted connection to a central pump that is housed externally to the controlled environment with filtered exhaust. Vacuum pumps and pipework can also be provided for process applications.

7 Water Supply & Drainage

Hot and cold water supply can be installed to handwash and utility sinks as well as process equipment that may have a demand.

Drainage can be accommodated either via pump or gulleys – for Pharmaceutical applications 316 stainless steel drainage and traps can be provided.

8 Nitrogen Generators

The Guardtech Group’s Nitrogen Generators are a reliable and efficient alternative to conventional high pressure cylinder and liquid gas supplies. Taking away the ongoing costs, safety considerations and transportation of traditional gas supplies, our generators are some of the most advanced and intelligent available.

The control system gives the user all the necessary information to ensure an efficient, consistent supply of gas is always available. From process to flow and alarms – including auto-start/stop functionality – trend graphs, service alarm and service records pages, these generators are well worth the investment.

DOWNLOAD DATA SHEET