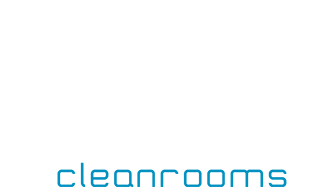

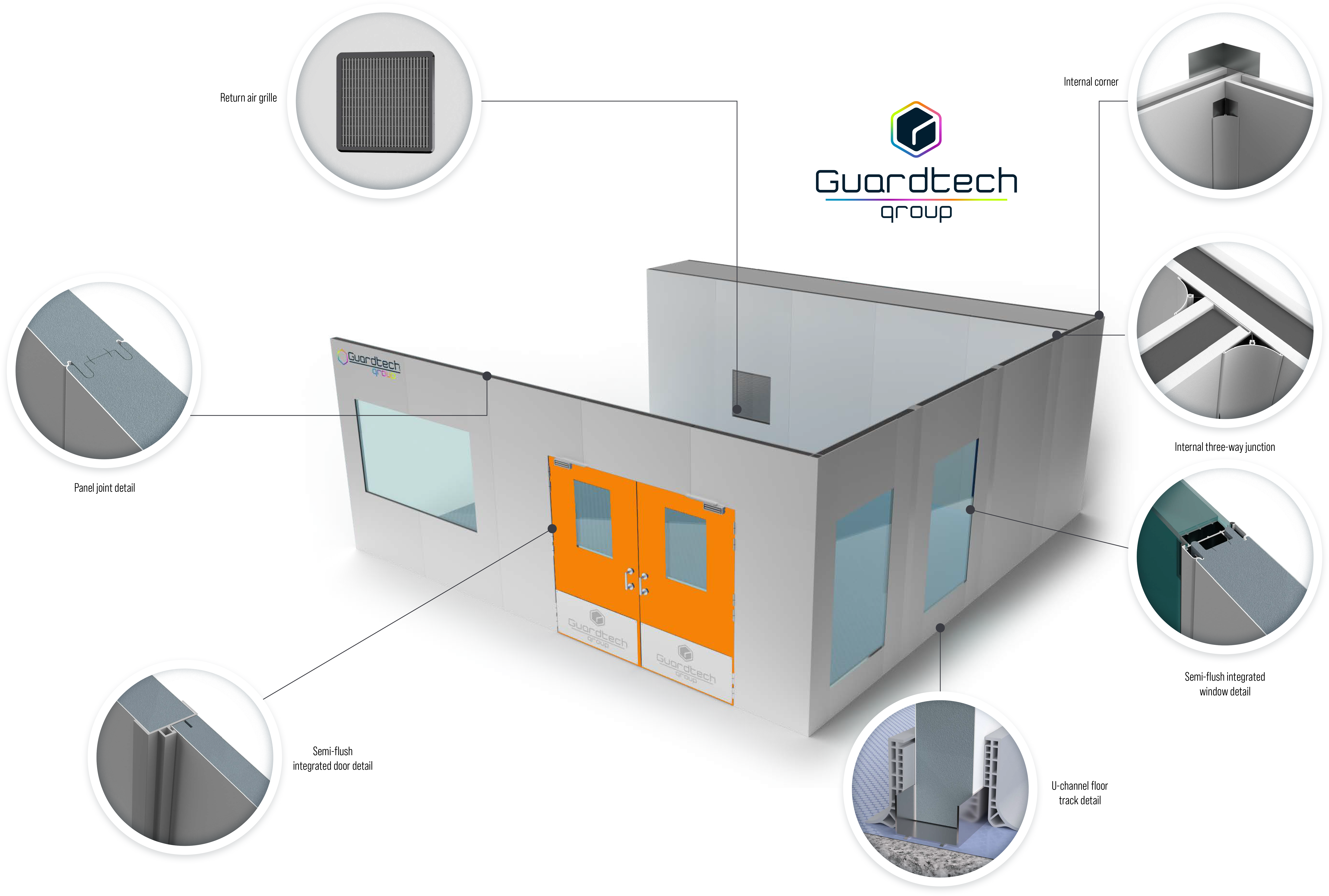

THE CNC Specification is designed to provide a cost-effective balance of components that will best suit lower-grade cleanrooms, laboratories and unclassified environments.

CNC utilises materials that are specified for lower-grade cleanroom builds whilst downgrading some of the mechanical & electrical interfaces to more standardised off-the-shelf components.

Structural materials are similar in composition to standard cleanroom builds, however, interfacing elements such as doors, windows, ceilings and flooring are typically more standardised, therefore the manner in which they interface and connect does not allow for a completely flush installation.

By utilising more common materials, efficiencies can be made with the budget, meaning that cost-per-m2 can be significantly reduced and manufacturing lead times shortened.

CNC SPECIFICATION TECHNICAL DATA

Components

-

Classifications Available

Controlled Not Classified

Classifications Available

Controlled Not Classified

-

Walls: GT Shell Plus

CLEANsafe insulated panels incorporating a panel joint that achieves excellent thermal performance and can accommodate vapour and hygiene safe seals. GT Shell Plus panels achieve low air leakage and resist moisture ingress and any risk of toxic mould and bacterial growth thanks to intelligent QuadCore insulation technology, with superior fire protection and enhanced environmental credentials via lifetime performance and high efficiency. download data sheet

Walls: GT Shell Plus

CLEANsafe insulated panels incorporating a panel joint that achieves excellent thermal performance and can accommodate vapour and hygiene safe seals. GT Shell Plus panels achieve low air leakage and resist moisture ingress and any risk of toxic mould and bacterial growth thanks to intelligent QuadCore insulation technology, with superior fire protection and enhanced environmental credentials via lifetime performance and high efficiency. download data sheet

-

Doors: GT Access Lite

Powder-coated steel door with a standard anodised aluminium frame, featuring ECOSafe PIR insulation core and a clear opening width of 1100mm (single) or 2200mm (double). 40mm door leaf thickness, available in XL forté and Spectrum external coatings and CLEANsafe internal coatings, including vision panels and aluminium kickplates as standard. download data sheet

Doors: GT Access Lite

Powder-coated steel door with a standard anodised aluminium frame, featuring ECOSafe PIR insulation core and a clear opening width of 1100mm (single) or 2200mm (double). 40mm door leaf thickness, available in XL forté and Spectrum external coatings and CLEANsafe internal coatings, including vision panels and aluminium kickplates as standard. download data sheet

-

Glazing: GT Vision Plus

Fully flush mounted glazed units consisting of aluminium frame and two panes of 6mm thick laminated glass, glued and silicone sealed on both sides to the frame. Frame features moisture-free silica-gel granules. Glazing panels slot into the holistic integrated envelope solution via extruded aluminium interface connection profiles. [download data sheet]

Glazing: GT Vision Plus

Fully flush mounted glazed units consisting of aluminium frame and two panes of 6mm thick laminated glass, glued and silicone sealed on both sides to the frame. Frame features moisture-free silica-gel granules. Glazing panels slot into the holistic integrated envelope solution via extruded aluminium interface connection profiles. [download data sheet]

-

Ceiling: GT Lid Lite

A 24mm lightweight powder-coated aluminium ceiling grid, suspended via galvanised wire thread with powder-coated composite board aluminium ceiling tiles. Silicon sealed on all edges and to perimeter walls. DOWNLOAD DATA SHEET

Ceiling: GT Lid Lite

A 24mm lightweight powder-coated aluminium ceiling grid, suspended via galvanised wire thread with powder-coated composite board aluminium ceiling tiles. Silicon sealed on all edges and to perimeter walls. DOWNLOAD DATA SHEET

-

Flooring: GT Deck Lite

Vinyl, hot-welded and coved 100mm from floor level, connection to wall via overlay onto the panel and finished with a rubber capping strip and silicone seal. download data sheet

Flooring: GT Deck Lite

Vinyl, hot-welded and coved 100mm from floor level, connection to wall via overlay onto the panel and finished with a rubber capping strip and silicone seal. download data sheet

-

Utilities Integration

Services are wall-mounted and contained within trunking and three-compartment dado rails. Pipework is surface-mounted, specification is generally powder-coated aluminium or stainless steel.

Utilities Integration

Services are wall-mounted and contained within trunking and three-compartment dado rails. Pipework is surface-mounted, specification is generally powder-coated aluminium or stainless steel.

-

Lighting: GT Lux Lite

Recessed LED panel, 5700k colour temperature, 3000 lumens per light fitting providing 500 lux at bench level. PIR motion sensor activated. download data sheet

Lighting: GT Lux Lite

Recessed LED panel, 5700k colour temperature, 3000 lumens per light fitting providing 500 lux at bench level. PIR motion sensor activated. download data sheet

-

HVAC & Filtration: GT Air Lite

Wall-mounted cassettes providing air conditioning via recirculated air matched with external condensers sized to overcome room heat gains and provide stable temperature control. download data sheet

HVAC & Filtration: GT Air Lite

Wall-mounted cassettes providing air conditioning via recirculated air matched with external condensers sized to overcome room heat gains and provide stable temperature control. download data sheet

-

Environmental Monitoring System: GT Scan Plus

In-room LED displays illustrating pressure, temperature and humidity, feeding back to centralised computer screen with GT Scan Plus EMS software for alarms and data storage. download data sheet

Environmental Monitoring System: GT Scan Plus

In-room LED displays illustrating pressure, temperature and humidity, feeding back to centralised computer screen with GT Scan Plus EMS software for alarms and data storage. download data sheet

-

Controls & BMS

Lights are controlled via PIR motion detection sensor, air conditioning controlled via wall-mounted digital display.

Controls & BMS

Lights are controlled via PIR motion detection sensor, air conditioning controlled via wall-mounted digital display.

-

Furniture

Standard units include: workbenches, stepover benches, cabinets, racking and dispensers manufactured from grade 304 stainless steel frames and Trespa TopLab work surfaces. Full fit-out available. To view the range CLICK HERE

Furniture

Standard units include: workbenches, stepover benches, cabinets, racking and dispensers manufactured from grade 304 stainless steel frames and Trespa TopLab work surfaces. Full fit-out available. To view the range CLICK HERE

-

Equipment

Standard units do not incorporate equipment. However, full fit-out available. To view the range CLICK HERE

Equipment

Standard units do not incorporate equipment. However, full fit-out available. To view the range CLICK HERE

Guardtech Group Make an Enquiry

Got a question for the Guardtech Cleanrooms team? Maybe you have a rough idea of what you want and just need to flesh out the finer details? Click the button below to contact the team now for a rapid response to your enquiry.

GUARDTECH GROUP CASE STUDY ISO5 DIAGNOSTICS REAGENT MANUFACTURING

Discover the design innovation, processes and challenges helped form this stunning 470sqm ISO5 manufacturing facility.

GUARDTECH GROUP CASE STUDY CNC QC LABORATORY

Discover the design innovation, processes and challenges helped form this wonderful 690sqm CNC QC laboratory.