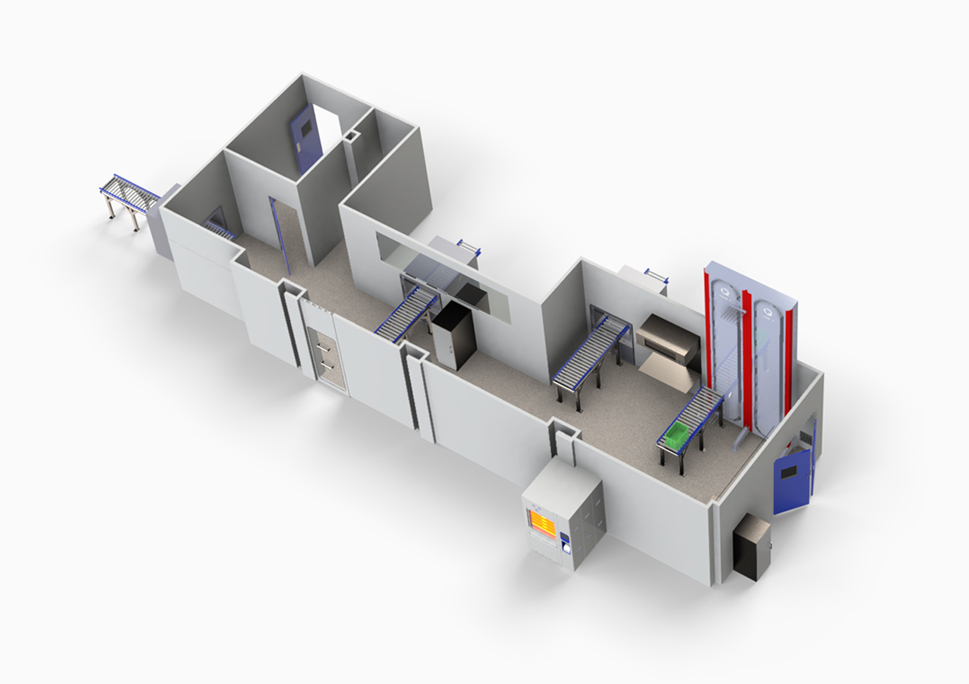

2D & 3D MODELLING

Guardtech Cleanrooms’ in-house Design team consists of specialist 2D (AutoCAD) and 3D (SolidWorks) Engineers.

- General arrangement layouts; structural, mechanical & electrical

- Process flow diagrams

- Elevations and sectional drawings

- HVAC P&ID, ductwork schematics, lighting layouts and wiring diagrams

- Pressure cascade diagrams

- Furniture & equipment layouts

- 3D models and animations

- Virtual reality facility walk-throughs

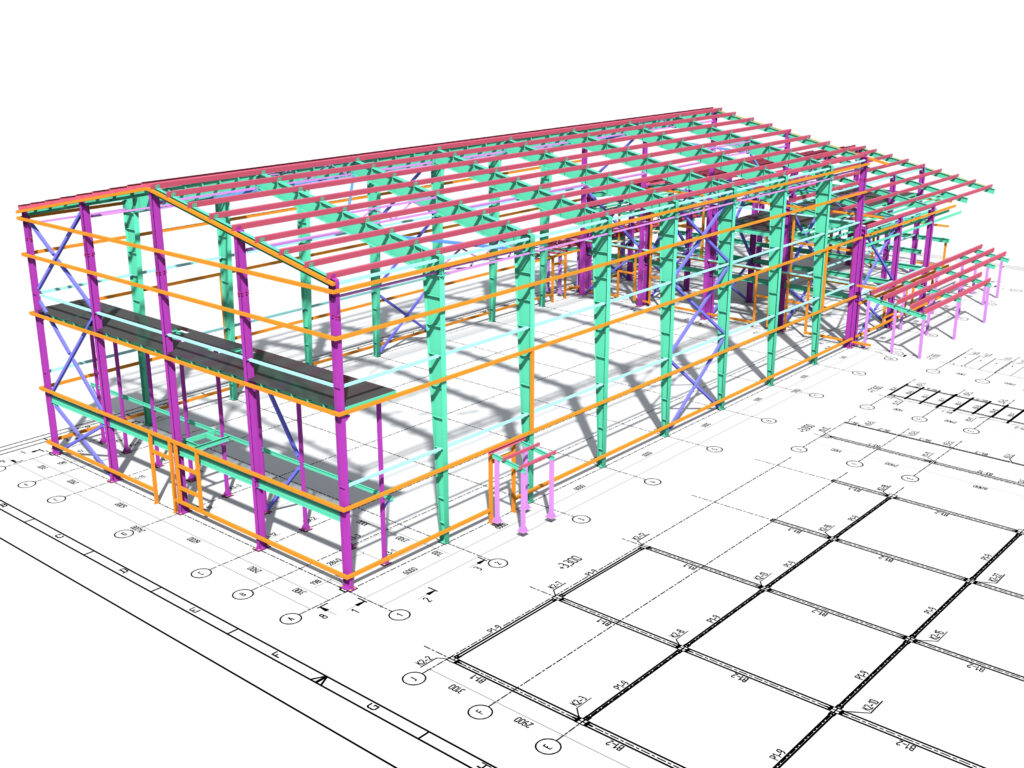

BUILDING INFORMATION MODELLING (BIM)

Guardtech utilise digital platform Revit for BIM – in which the building is a live element which contains critical information.

- Sections, plans, elevations, 3D views, schedules and material lists can be extracted from model

- Revisions reflected simultaneously to all extracted data representations

- Bidirectional connection for full automation

- Removes need for manual updates

- Fast, effective, robust tool for managing multi-contractor projects

- Avoid conflicts through clash detection of confederated models

- Supports highly accurate Bill Of Materials (BOM) compilation, ensuring accuracy with on-site provisions and components

- Reduces waste and increases productivity

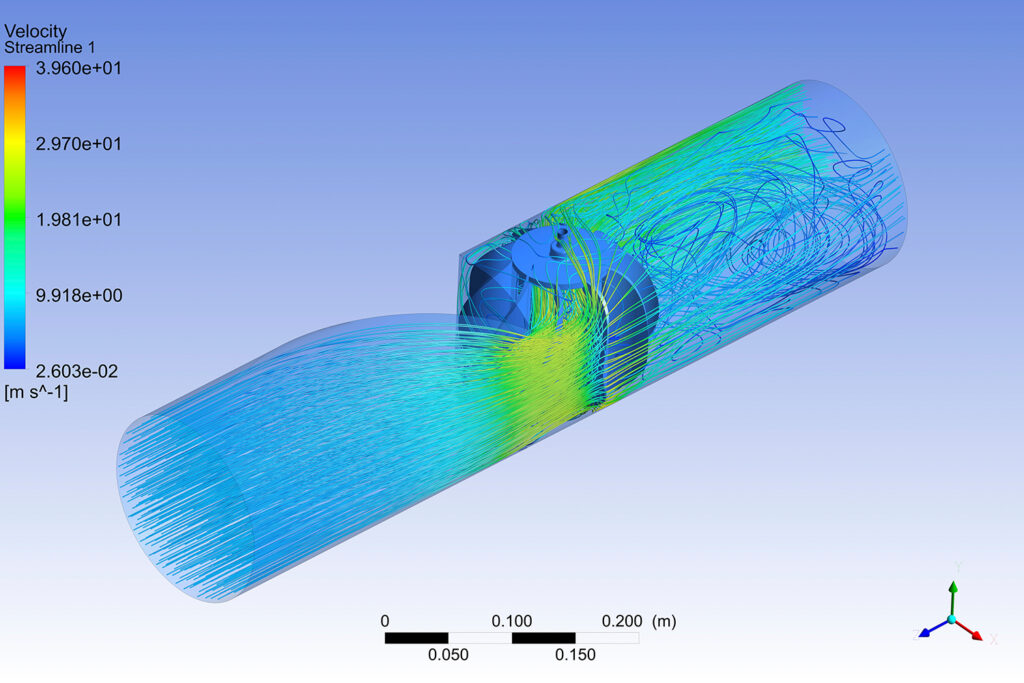

Computational Fluid Dynamics (CFD)

CFD enables airflow within cleanrooms to be simulated during the design phase, providing visualisation, insight and guidance into:

- Optimised airflow configuration, reducing dead spots and increasing uniformity and coverage

- Temperature and humidity mapping throughout the space, relating to heat sources within the room and their relation with conditioned supply air

- Reducing energy consumption by evaluating air changes required per hour

- Supply diffuser and exhaust vent positions

- Appropriate sensor positioning

- Comparative flow distribution for smoke test validation and room recovery testing

CONSULTATION

You’ll deal with dedicated industry professionals who pride themselves on listening, understanding and unearthing your exact needs and requirements.

- We work with your fully developed brief or URS (User Requirement Specification)

- Achieve the best value solution for your application – balancing specification with budget

- Consider the restrictions imposed by the host building

- Provide in-depth needs analysis to determine the most appropriate process flow, classification and configuration of room layout

- Understand your process requirements, including equipment and supporting utilities

- Determine room performance specification and balance needs of process, product and operators

- Considering ongoing running costs, maintenance and redundancy

- Support in specifying design and installation of all plant and process utilities

- Understand the future needs of the business

DOCUMENTATION

Detailed and comprehensive documentation is produced to aid the design process and support cGMP compliance.

This information is compiled in response to the client brief and provides a contractual framework, a fully developed scope of works and a defined performance specification.

- Master Room Specification: Excel documentation that captures specific parameters pertaining to the design

- Functional Design Specification: Outline of the design concept for all structural, mechanical and electrical systems

- Design Qualification (DQ): For all cGMP projects a full design qualification can be produced in response to the URS outlining compliance to the brief whilst initiating a framework for the later commissioning stages of Installation Qualification (IQ) and Operational Qualification (OQ).

LASER SCANNING

Guardtech Cleanrooms have embraced the next level of design technology by incorporating 3D laser scanning into the beginning of their process as a detailed room information data capture.

- Cutting-edge technology from industry leaders Leica

- Full 680,000-point-per-second scan with spherical images can be captured within 20 seconds

- Maximum scan distance of 60 metres at an accuracy of 4mm tolerance

- Entire facilities can be transferred into an accurate 3D model

- Site survey can be completed in as little as one hour

- Information this provides is invaluable to design process and enables for full clash detection and exact confines and restrictions of host building

- Detailed scan identifies issues far earlier in process, prior to manufacturing of components or attendance on-site

- Benefits to the client are cost assurance and time-frame confidence, as challenges are encountered and overcome at the design stage rather than disrupting construction

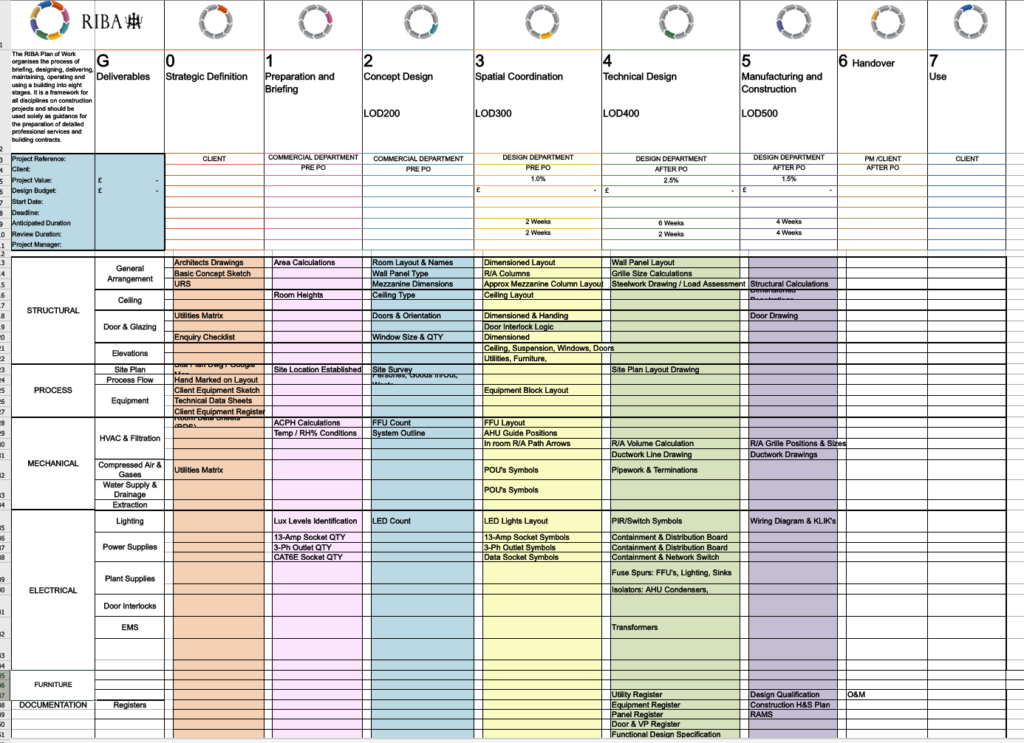

RIBA FRAMEWORK

The RIBA Plan of Work was initiated in 1963 to provide a framework for architects to use on projects with their clients, bringing greater clarity to the different stages of a project. Guardtech have developed their own framework that closely mirrors the stages of RIBA and includes the following:

- 0 – Strategic Definition: Client-provided drawings, URS, equipment & utilities register, process flow, enquiry checklist

- 1 – Preparation & Briefing: Concept layout sketch, area calculations, performance criteria, host building information

- 2 – Concept Design: Developed general arrangement – structural, mechanical, electrical, room data sheets

- 3 – Spatial Co-ordination: Dimensioned drawing pack with developed master specification and site plan

- 4 – Technical Design: Full 2D issued drawings for each specific area of construction, registers, calculations, schematics

- 5 – Manufacturing & Construction: Signed off approved drawings for installation

- 6 – Handover: O&M’s, commissioning documentation reports

Guardtech Group Make an Enquiry

Got a question for the Guardtech Cleanrooms team? Maybe you have a rough idea of what you want and just need to flesh out the finer details? Click the button below to contact the team now for a rapid response to your enquiry.